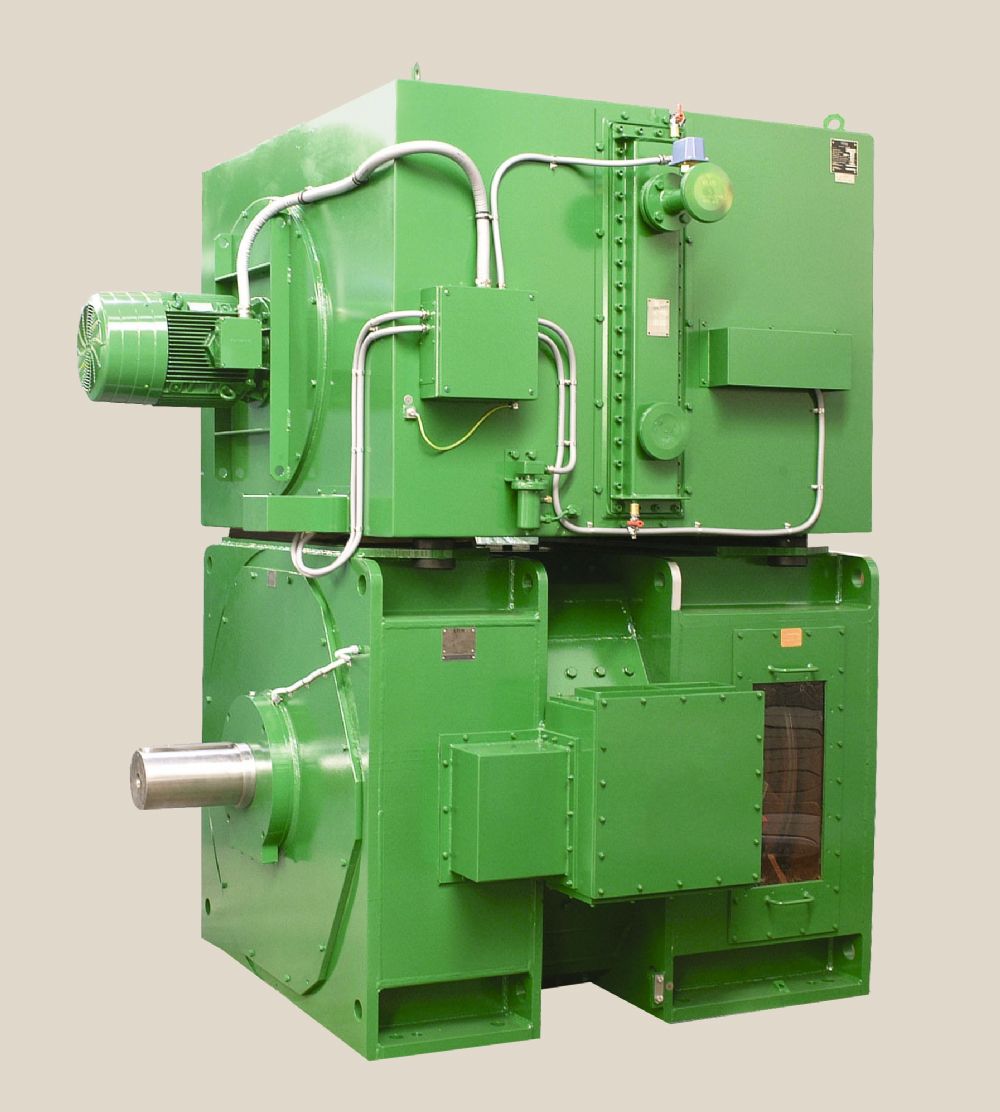

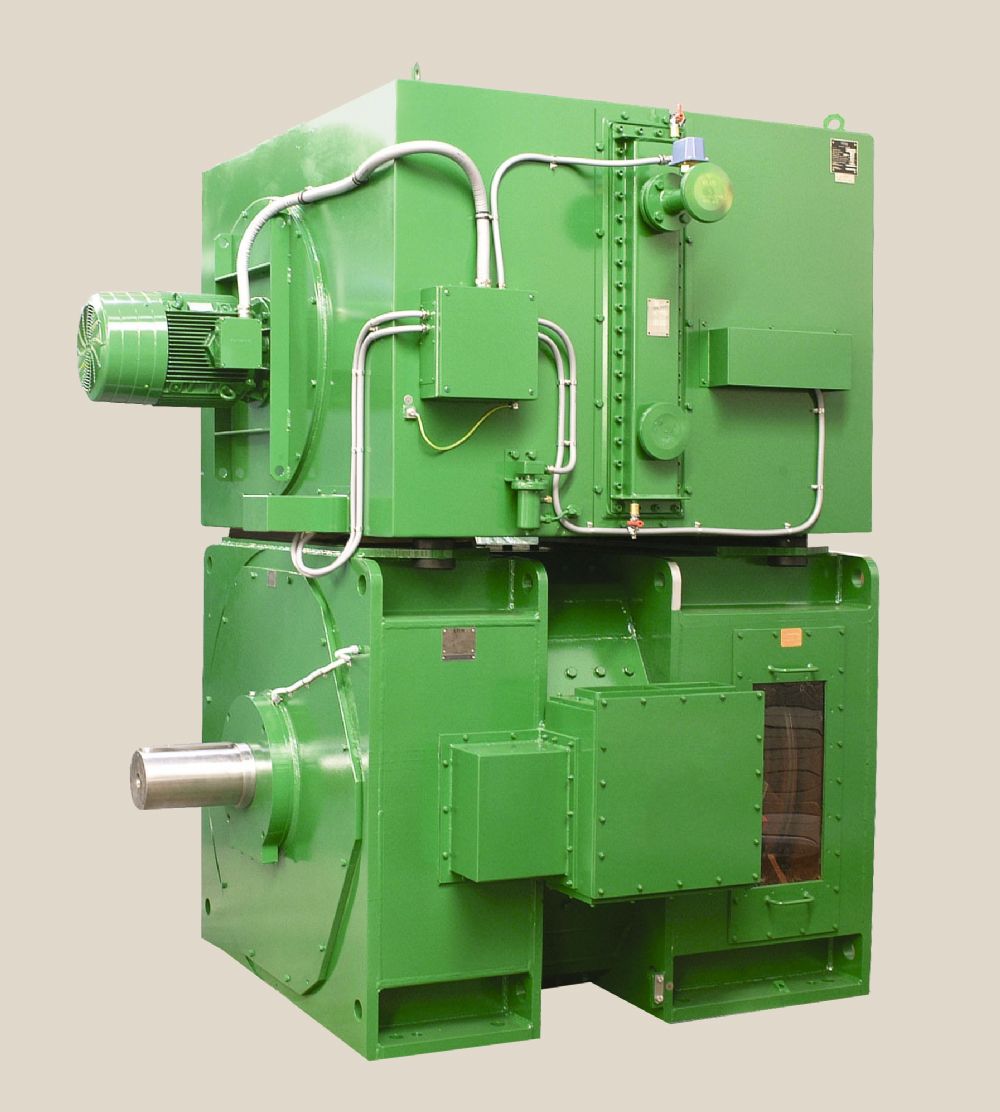

DC Machines

Each machine is specially designed for a specific application. Our product range extends from small DC machines to very large units.

Each machine is specially designed for a specific application. Our product range extends from small DC machines to very large units.

LDW is a leading center of excellence for DC machines. Our expertise has developed and been proven over decades. As one of the few manufacturers operating globally, we can replace other manufacturers' machines with an LDW machine, taking into account both electrical and mechanical characteristics. Each machine is specifically designed for its intended application, and our product range spans from small DC machines to very large units.

All machines are individually manufactured according to our customers' requirements.

In recent years, continuous research and development have improved the field performance of DC motors and reduced maintenance requirements. Thermal and magnetic efficiency has been enhanced, and materials optimized, resulting in a significant increase in brush life.

Performance Specifications

LDW produces DC motors and DC generators in the power range of 50 to 8,000 kW.

Other Machine Features:

Shaft heights: 160 to 1,000 mm for square designs, larger for round designs

Torque range: 20 to approximately 900,000 Nm

Speeds up to 10,000 rpm

Special Features

Reliable operation in the most demanding conditions

High control dynamics

Compact, space-saving design

Flexible excitation options

Extensive range of proven and tested accessories

Custom design capability

All common designs, protection classes, and cooling types

Versions for hazardous areas (Zone 1 and Zone 2) with explosion protection types overpressure enclosure Ex "px" and Ex "pz"

Advantages

DC machines have high power density, are compact, and suitable for a wide range of applications. Our machines represent the latest technology and meet all current requirements in mechanical and plant engineering. LDW DC machines offer excellent control characteristics and clear control structures.

These machines operate quietly, with excellent concentricity and high starting torque from standstill. DC machines do not experience voltage spikes, reducing insulation stress. They have high electromagnetic compatibility, minimizing the need for additional measures to reduce interference and improve immunity.

Additional Advantages:

Easy to use

Wide adjustment range from very low to very high speeds

High dynamics with rapid current rise

Especially smooth operation

Compact design

Grid-feedback capability for energy savings

Low maintenance

High electromagnetic compatibility

Equipment

LDW produces DC machines with all common protection and cooling systems. Machines are available in horizontal or vertical configurations and can be customized to customer requirements. Square designs make LDW DC machines extremely compact and adaptable to operational conditions on-site. Configurations with shaft heights up to 315 mm can include 90° rotatable square terminal boxes, allowing axial cable entry. Integrated radial fans are optimally positioned with minimal protrusion.

LDW motors are manufactured according to the "H" thermal class (up to 180 °C). When operated according to the "F" class (up to 155 °C), the insulation material and consequently the winding lifespan is extended.

We offer various cooling options to ensure optimal machine cooling: from self-cooling, surface-cooled machines to externally cooled, air-air or air-water heat exchangers, or internally cooled systems.

Our DC machines are designed to be compatible with speed encoders and standard brakes. Using standard components allows for horizontal or vertical mounting. Heat exchangers, piping, and a wide range of proven accessories can be added as needed. The brush assembly is user-friendly, making brush replacement quick and easy.