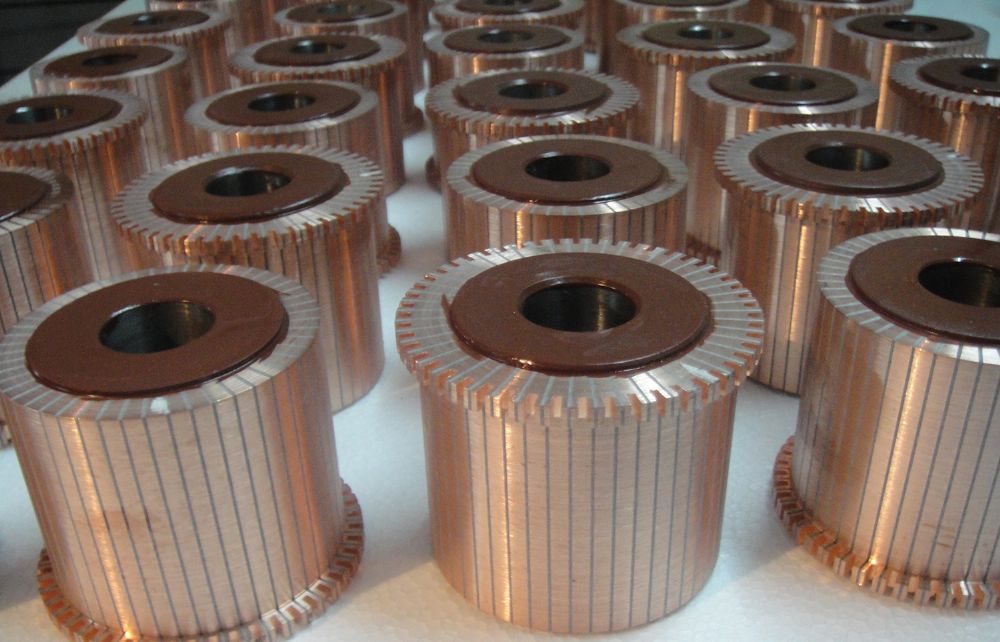

Molded Commutators

Molded Commutator manufacturing involves following stages

Raw Matrial:

- Hard Drawn electrolytic (99.9%;purity) or Silver Bearing Copper (0.1% Silver) is used. Silver bearing copper offer better heat resistance and bearing properties (Low wear of carbon brushes even at relatively higher temperatures.)

- Separator Mica - For "H" Class insulation Alkyd Vinyl Bonded Mica & for "F" Class insulation Shellac Bonded Mica is recommended. We use Alkyd Vinyl Bonded Mica (finely ground resin bonded).

- Commutator molding material - Thermoset glass-reinforced DMC based on unsaturated polyester resin, this molding material possesses superior mechanical strengths, temperature resistance beyond 250°C, very high electrical insulating strengths, especially arc & track resistance and is fire retardant.

Process:

- Copper lengths (normally multiple of segment length) received in trapezoidal form are cut to Segment Length (Segment length is Brush Length + Riser Width) with machining allowance.

- Segment is punched into 'L' shaped & 'V' grooves (with machining allowance for plain & profile turning). Separator Mica is punched as per Copper segment with additional length for Mica Projection on Riser side.

- Punched Copper Segments & mica segments are held secured in specially designed collet fixture. Assembly is retained in position by insulated steel rings at both ends.

- Commutator is molded by heat gelation process in specially design hydraulic press / fixture.

- Molded Commutator is then machined and tested as per customer's specifications.

Quality & Testing:

- Dimensional check using precision measuring instruments.

- Spin test - Commutator is checked for segment / bar rise on diameter in spin test.

- Hipot Test - Segment to Segment and Segment to Earth Hipot test.

- Insulation Resistance - Megger Test for Insulation Resistance.

TR

TR EN

EN AR

AR